-40%

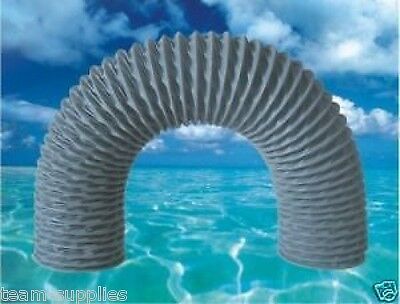

16 inch Silver Flex Insulated Flex Duct R6 25 FEET

$ 121.41

- Description

- Size Guide

Description

PHYSICAL DESCRIPTION FEATURES & BENEFITSMHP-25 (25’ length) flexible duct is constructed UL Listed & Labeled with a spring steel wire helix, encapsulated in a Guaranteed out of package lengths 2-ply, air-tight inner core.

Fiberglass insulation 10 Year limited warranty choices of R6 encompass the core and GREENGUARD Gold Certification a unique metalized, reinforced vapor barrier Formaldehyde free (see www.jplflex.com for more info) surrounds the entire duct. 3/8” oversize inner core Certified R-Values

PRODUCT DATA Diameters: 4”,5”,6”,7”,8”,9”,10”,12”,14”,16”,18”,20”,22” CODE COMPLIANCE & APPROVALS * 22” available in MHP25R6 only Listed & Labeled Underwriters Laboratories, Length: 25 feet Inc. File # MH11637 UL-181 Class 1 Air Duct, Packaging: 1 section per poly-bag or carton. To meet Flame Spread 25 or Less / Smoke Developed thermal properties, packaging complies with 50 or Less.

Meets the requirements of NFPA recommended 12:1 or less compression ratio. 90A & 90B, UMC & IMC and most model codes Vapor Barrier: 2-Ply Reinforced Metalized Polyester California Insulation Manufacturer #TD-1092 End Treatments: Raw Ended Inner Core: Air Tight 2-Ply Black Pigmented Polyester PERFORMANCE DATA Thermal Value: R4.2, R6 & R8 Classified by Underwriters Laboratories, Inc. and bears the ADC Thermal Certification Mark.

Maximum Positive Pressure: 6” W.G. (4” – 12”) 4” W.G. (14” – 22”) determined per ADC Test FD-72R1 at 180° F temperatures in a 90° elbow. Maximum Negative Pressure: 1” W.G. (4” – 10”) ½” W.G. (12” – 22”) Vapor Barrier: Flexible air ducts are for indoor applications and should not be exposed to direct ultraviolet light. Maximum Velocity: 5,000 FPM Operating Temperatures: 0 - 200° F Permeance: (Vapor – Barrier) 0.01 US Perms per

PRODUCT DATA Diameters: 4”,5”,6”,7”,8”,9”,10”,12”,14”,16”,18”,20”,22” CODE COMPLIANCE & APPROVALS * 22” available in MHP25R6 only Listed & Labeled Underwriters Laboratories, Length: 25 feet Inc. File # MH11637 UL-181 Class 1 Air Duct, Packaging: 1 section per poly-bag or carton. To meet Flame Spread 25 or Less / Smoke Developed thermal properties, packaging complies with 50 or Less.

Meets the requirements of NFPA recommended 12:1 or less compression ratio. 90A & 90B, UMC & IMC and most model codes Vapor Barrier: 2-Ply Reinforced Metalized Polyester California Insulation Manufacturer #TD-1092 End Treatments: Raw Ended Inner Core: Air Tight 2-Ply Black Pigmented Polyester PERFORMANCE DATA Thermal Value: R4.2, R6 & R8 Classified by Underwriters Laboratories, Inc. and bears the ADC Thermal Certification Mark.

Maximum Positive Pressure: 6” W.G. (4” – 12”) 4” W.G. (14” – 22”) determined per ADC Test FD-72R1 at 180° F temperatures in a 90° elbow. Maximum Negative Pressure: 1” W.G. (4” – 10”) ½” W.G. (12” – 22”) Vapor Barrier: Flexible air ducts are for indoor applications and should not be exposed to direct ultraviolet light. Maximum Velocity: 5,000 FPM Operating Temperatures: 0 - 200° F Permeance: (Vapor – Barrier) 0.01 US Perms per

N FE